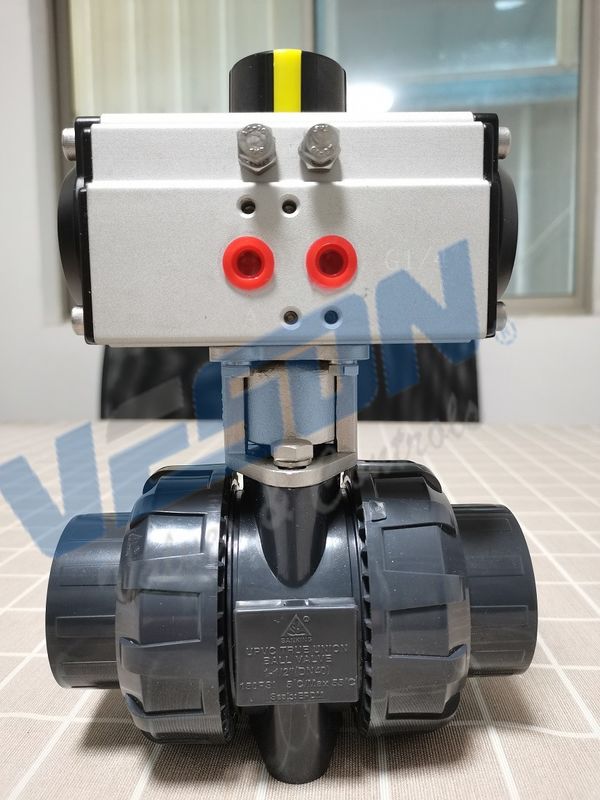

Pneumatic Actuated PVC Ball Valves / PVC Ball Valve With Double Acting Pneumatic Actuator.

Product Details:

| Place of Origin: | China |

| Brand Name: | Veson/OEM |

| Certification: | ISO/CE/SIL3 |

| Model Number: | VS-052DA |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Ea |

|---|---|

| Price: | FOB Shanghai |

| Packaging Details: | Carton/Plywood case |

| Delivery Time: | One week |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10000PCS/Month |

|

Detail Information |

|||

| Material: | Aluminum Alloy | Type: | Pneumatic Actuator |

|---|---|---|---|

| Function: | Quarter Turn Actuator | Valve: | Pneumatic Piston Actuator |

| Standard: | ISO5211 | Valve Type: | Plastic Valve |

| Highlight: | pneumatic air valve,pneumatic pressure control valve |

||

Product Description

ADVANTAGES:

1) USA NSF approved & materials meet drinking water standard

2) Smooth opening & closing thanks to a lower torque

3)The material has been modified by nanometer,improving the pressure resistance and impact resistance

4)Raw materials add anti ultraviolet absorbent and antioxidant, improving the durability, ageing resistance

5) 100% pressure testing before leaving the factory

DESCRIPTION:

1) Material:UPVC,CPVC,PPH,PVDF,HT-CPVC

2) Size:1/2''-4'';20mm-110mm;DN15-DN100

3) Standard:ANSI,DIN,JIS,CNS

4) Joint End:Socket,Threaded(NPT,PT,BSPF),Fusion,Welding

5) Working Pressure:150 PSI

6) Operating Temperature:UPVC(5~55℃);CPVC&PPH(5~90℃);PVDF(-20~120℃);

HT-CPVC(5~90℃)

7) Handle color:red,blue,green,orange

Valve body color:UPVC(dark gray),CPVC(light gray),PPH(light yellow)

Clear PVC(transperance),PVDF(ivory),HT-CPVC(light yellow)

![]()

DESIGNS:

- Underside handle extends the length so that both OFF block will not be exposed, more beautiful

② Extrusive circular plane change to both side plane, easy processing and assemble

③ Lateral plane and ribs of the Union Cap, from the right-angle change to incline to increase the intensity

④ Union end from right-angle to slope increase in a round protruding rib to increase the intensity

⑤ Surface of Oring change to a plane, and each have been cutting lathe in order to ensure its flatness

⑥ Seal carrier and Oring slot is processed by machine, sealing performance is improved.

⑦ Each ball has increased turning and grinding to ensure that its true roundness and smoothness. So much easier to handle and not easy leak

⑧ Inside body is processed via CNC machine to make sure acurate dimensions

⑨ Increase the slope of trapezoidal teeth and the number of teeth in order to ensure their connection strength

⑩ Through hole is processed via CNC machine to make sure the stability of sealing

(11) Slot dimension is improved, sealing performance is strengthened.