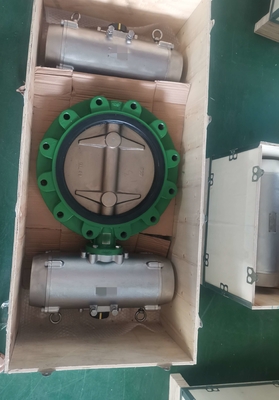

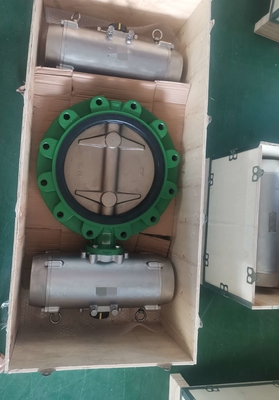

304 SS Presentation Dampers Pneumatic Butterfly Valve Presenting Double Flange Damper

Product Details:

| Place of Origin: | China |

| Brand Name: | VESON |

| Certification: | ISO CE |

| Model Number: | VS-140SR08FO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Fob Shanghai ,EXW |

| Packaging Details: | plywood case with reforinced packing |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 |

|

Detail Information |

|||

| Butterfly Valve: | Wafer Type | Type: | Double Acting Or Spring Return |

|---|---|---|---|

| Name: | Air Operated Butterfly Valve | Pressure Range: | 25mm - 200mm: 16 Bar 250mm - 300mm: 10 Bar |

| Temperature Range: | -10oC To 120oC | Application: | General |

| Highlight: | wafer type butterfly valve,on off butterfly valve |

||

Product Description

For shutting off, controlling, diverting or reducing the flow of corrosive and chemically-polluted exhaust air, flue gases and process gases, for example in:

• Domestic and special waste incinerators

• Denitrification and flue gas desulphurization plants (DeNOxand FGD plants)

• Thermal power plants (e.g. gas turbine plants)

• Smelting works, production of precious and special metals, e.g. steel, copper, gold, silver, platinum, titanium, palladium

• Cement works and mineral oil refineries

• The process industry (chemicals, pharmaceuticals, foodstuffs) and the semiconductor industry

|

Topic |

Dampers Pneumatic Butterfly Valves Description |

|---|---|

| Construction | Valve body made of cast iron, stainless steel, or carbon steel |

| Disc or plate mounted on a central shaft | |

| Dampers | Additional components for enhanced control and damping capabilities |

| Actuation | Pneumatic actuators commonly used |

| Control Signal | Pneumatic pressure signal received from a control system |

| Applications | HVAC, water treatment, chemical processing, power generation, etc. |

| Advantages | Compact design, quick operation, low torque requirements |

| High flow capacities, improved stability, reduced noise | |

| Maintenance | Regular inspection, lubrication, and component replacement |