Multifunctional Automatic Recirculation Valve For Chemical Industry

Product Details:

| Place of Origin: | China |

| Brand Name: | Veson |

| Model Number: | ARL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Packaging Details: | Plywood package |

| Delivery Time: | 6-8 WEEKS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 |

|

Detail Information |

|||

| High Light: | Chemical Industry Automatic Recirculation Valve,Multifunctional Automatic Recirculation Valve,Mechanical Automatic Recirculation Check Valve |

||

|---|---|---|---|

Product Description

Product Description

For Pump Protection

The modern industrial equipment process request centrifugal pump basically works under the condition of variable flow.

An automatic recirculation valve (ARC valve) is a multifunctional valve whose primary purpose is to ensure that a pre-determined minimum flow is assured through a centrifugal pump at all times. This is important as centrifugal pumps suffer from overheating and cavitation and can be permanently damaged if they run dry.

Through many years of research and development, continuous innovation and practice, shanghai dating valve Co. research ZD series Automatic recirculation control Valve, to prevent overheating, serious noise, unstable and erosion damage of centrifugal pump under low load operation. As long as the flow rate of the pump valve below a certain value, the bypass backflow mouth will automatically open to ensure the necessary minimum flow of the pump.

Applications Of ARC Valve

- Chemical industry

- Petrochemical industry

- Steel factory

- Fire protection system

- Traditional power plant

- Paper-making industry

- Shipment/shipping

- environmental protection industry

Centrifugal Pump Protection Scenarios Using ARC Valve (ARV)

Three protection ways for pump

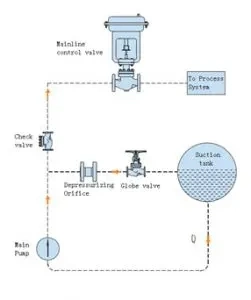

Continuous Circulating System

Minimum requirement of continuous circulating system pump is unrelated to the discharge of Process flow changes system. After setting of minimum flow, through orifice plate directly backflow to a storage tank. Although continuous minimum flow circulation can protect the pump very good, the pump must provide greater power output to ensure system process flow plus recycle flow, which causing additional energy waste.

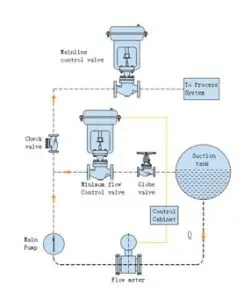

Control Circulating System

Control circulatory system is assembly by the check valve, flow gauge, minimum flow control valve, control circulation system, control circulation system can provide minimum flow protection, when process flow is greater than the minimum flow of the pump, loop closed, no extra energy loss. But the system is complex, control components, purchase, installation, maintenance cost is higher.

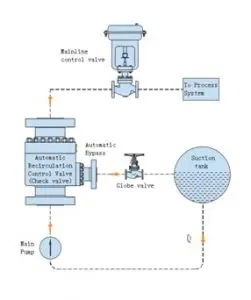

Automatic Recirculation Control Valve

Automatic recirculation valve set check valve, flow perception, bypass control valve, multi-stage step-down in one, do not need power, control system and wiring, essential safety. Taking up small space, reducing the possibility of high-speed fluid to malfunction to a minimum, with lower installation and maintenance cost, It is the priority pump protection way of the modern industrial process.

The Main Advantages Of AR Series Automatic Recirculation Control Valve

ZD series ARC valve is suitable for bypass with high-pressure differential, a maximum pressure differential is 30MPa, and the specific choice is determined by the factory. Multistage decompression type M type bypass can eliminate noise made by high-speed flow medium, prevent damage of cavitation erosion, and braising to valve components.

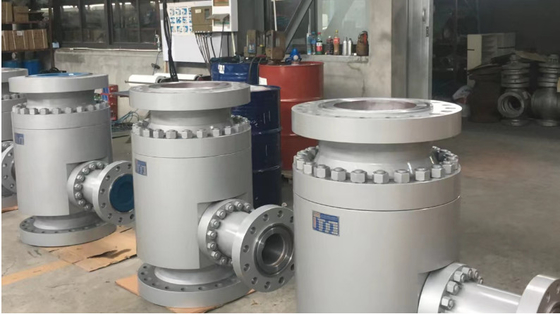

ART Model ARC valve

- Simple structure, low cost, long life, suitable for Low-pressure Working conditions.

- Cast valve body, material: carbon steel or stainless steel, etc.

- The big flow of bypass, maximum flow is 60% of the main flow, KV value can be adjusted.

- Bypass maximum operating pressure differential up to 4 MPa.

- Pressure CL150# - 400#, size1'' - 16''.

ARL Model arc valve

- Multi-orifice cage bypass, low noise, suitable for middle and low-pressure conditions.

- Forged steel body, material: carbon steel or Stainless steel, etc.

- Non-return valve function is standard, Maximum pressure differential up to 6 MPa.

- With venturi port main flow check valve structure, be applicable for complicated working conditions.

- Pressure CL150# - 600#, size1'' - 20''.

- Manual bypass operation is optional.

ARM Model ARC valve

- Multistage decompression to preventing cavitation, reducing velocity, suitable for high-pressure conditions.

- Forged steel body, material: carbon steel or Stainless steel, etc.

- Non-return valve function is standard, Maximum pressure differential up to 30 MPa.

- Pressure CL150# - 2500#, size1'' - 20''.

- Manual bypass operation is optional.

Automatic Recirculation Valve Working Principle

According to the difference of inductive main flow, the main valve disc check cone of the ARC valve will automatically move to a certain position. At the same time, the main valve disc drives the bypass valve stem, transfers the movement of the main valve disc to bypass, through control bypass valve disc position, changes the bypass throttling area, so as to control bypass flow. When the main valve disc back into the valve seat closed, all flow backflow through the bypass. When the valve discs rise to the top position, the bypass is fully closed, all the flow of pump flow to the processing system. This valve set four functions in one body.

- Flow perception: ARC valve main valve disc can automatically perceive the main flow of the processing system, thereby according to the flow to determine the position of the main valve disc and bypass disc.

- Recirculation control: ARC valve can inhaled pump normal operation required minimum flow into storage device through the bypass, so as to adjust pump H - Q characteristics, to realize recycling.

- Bypass multistage pressure reducing: bypass control system can reduce the backflow medium from the high-pressure pump outlet to appropriate backflow to the low-pressure storage device with low noise small wear.

- Check: The automatic recirculation valve also has a check valve effect, preventing the liquid backflow to the pump body. Bypass non-return function is standard.

- A special bypass size can be customized. The max flow rate of the bypass is subject to the max Kv value.

| Property | Description |

| Function | ARC valve Protects pumps from damage caused by low flow conditions by automatically recirculating a small portion of the pumped liquid back to the pump inlet |

| Types | Mechanical, electronic, and hydraulic |

| Additional features | Pressure relief valves, flow meters, or temperature sensors |

| Applications | Oil and gas processing, chemical manufacturing, power generation, and water treatment |

| Pump type | Typically used with centrifugal pumps |

| Factors to consider | Flow rate, pressure, temperature, and specific application requirements |

| Importance of installation, maintenance, and testing | Critical to ensure optimal performance and reliability |